Quality screen printed ceramic decals

What are ceramic decals?

Ceramic decals are specialised designs or patterns that are printed onto a carrier paper and later transferred onto ceramic surfaces by manual and automated process.

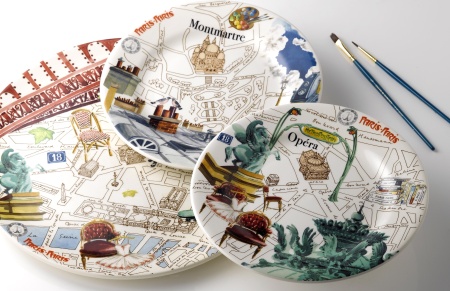

These decals are made using ceramic pigments, which can withstand the high temperatures of firing in a kiln. They are commonly used to decorate items such as plates, mugs, tiles, vases, and sanitary-ware, allowing intricate designs to adhere permanently to the ceramic surface.

The production of ceramic decals is a sophisticated process that relies on highly skilled professionals that have many years experience in the field.

Our expert team will guide clients using their extensive knowledge in the process.

Ceramic decal manufacturer

Uses and applications

- Ceramic decals are widely used in the manufacturing of home décor items, such as vases, tiles, and tableware.

- Decals for ceramics are also utilised in the hospitality industry, where branding on plates, cups, and saucers plays a key role in reinforcing a restaurant or hotels identity.

- The sanitary-ware industry use decals to enhance the visual appeal and individuality of products such as sinks and toilets. Each piece is branded with the manufacturers company logo.

- Architectural designers use ceramic decals in creations such as mosaics, decals can be used to add intricate designs or patterns onto tiles, walls, or other ceramic surfaces.

- Ceramic bottles for spirits can be decorated with intricate designs, logos, or vibrant artworks.

Common questions

Ceramic decals require specific firing temperatures to ensure proper adherence to the surface. The ideal temperature typically depends on the type of decal being used, as well as the composition of the ceramic piece. For low-fire decals, firing temperatures usually range between 1420°F (770°C) and 1650°F (900°C). Inglaze decals, on the other hand, may require temperatures closer to 2000°F (1093°C). SIAK's laboratory team will assess the substrate, and required result to give precise guidance into the final options for firing.

Ceramic decals, while versatile and vibrant, do have certain color limitations due to the materials and firing processes involved. The range of colors that can be achieved is often restricted by the pigments and oxides that are stable at high temperatures. Bright and vivid colors, such as certain shades of red and pink, can be particularly challenging to produce consistently, as they may require additional care or special formulations to withstand the firing process. Similarly, achieving pure whites can sometimes be difficult, as the base material or glaze may influence the final appearance. These limitations mean that careful planning and testing are essential when designing with ceramic decals to ensure the desired colour outcome.

Get in touch

International enquiries welcome

- +44 (0) 1782 839464

- +44 (0) 1782 839464

- sales@siaktransfers.com