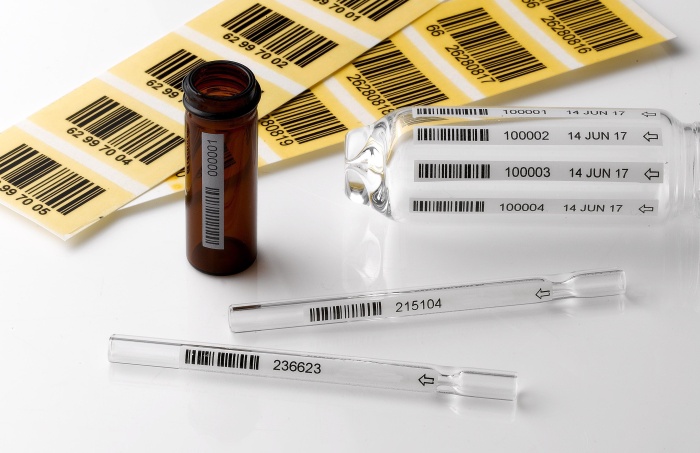

Sequential barcoding decals for sanitaryware

Sanitaryware sequential barcodes

Sanitaryware barcodes are used to track and manage items like toilets, sinks and bathtubs throughout the production process, from casting to shipping.

These barcodes are typically printed (or placed by decal) onto the ceramic pieces, often before firing, using specialised ceramic inks that can withstand high temperature (up to 1250 degrees Celsius). They enable efficient tracking of inventory, production stages and quality control.

Barcodes decals

Uses and applications

- Production tracking

- Inventory management

- Quality control

- Integration with software

- Customisation

Common questions

The decals are printed onto a gum based paper and placed into water to release. As the decals are typically placed directly onto cast greenware with a powder glaze spraying, it is necessary to apply a small amount of slosh (solvent fixative) to the piece prior to application.

All types of barcodes are available for this process - EAN, QR, Data Matrix etc

Get in touch

International enquiries welcome

- +44 (0) 1782 839464

- +44 (0) 1782 839464

- sales@siaktransfers.com