Heat release decals manufacturer

Heat release decals

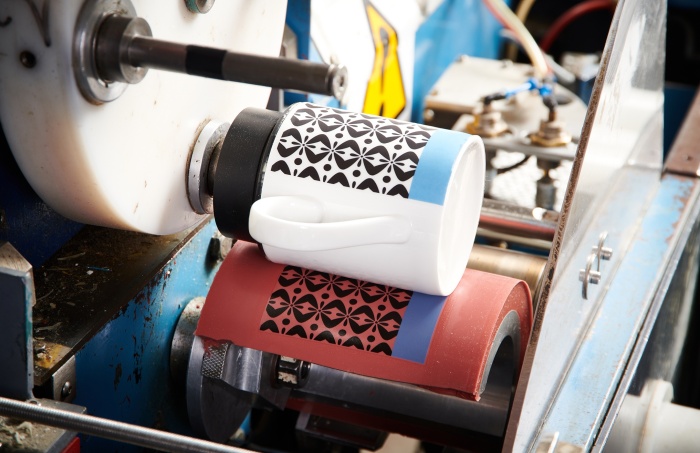

Automated decals for ceramics have revolutionized the way intricate designs are applied to ceramic products. This technology enables the precise transfer of detailed patterns, logos, or artwork onto ceramic surfaces, ensuring uniformity and reducing production time.

By automating this process, manufacturers can achieve higher efficiency and consistency compared to traditional hand-applied methods. Additionally, automated decals allow for greater creative freedom, as complex designs can be reproduced with accuracy, making them ideal for both functional and decorative ceramic items.

High colour counts can be applied in one application. Complex curves and recesses are printed when decoration by hand is problematic. The heat release decal utilises technology similar to that of the pad printing process. Decals are first warmed on a heater plate to melt the wax substrate, and are then picked up by a hot silicone pad that transfers the decal to the glass or ceramic piece.

Heat release decal supplier

Uses and applications

- Decoration of plates and bowls

- Mug decoration

- Spirit and cosmetic glass

- Increase in decoration speeds

- High accuracy repeatability

Videos

Common questions

Automated decals for ceramics differ from manual ones primarily in their application process and efficiency. With manual decals, skilled artisans carefully place and adjust each decal onto the ceramic surface by hand, which can be time-intensive and prone to slight inconsistencies. On the other hand, automated decals utilize advanced machinery to precisely position and apply the designs, ensuring uniformity and reducing the time required for production. Essentially though, the composition of the actual decal inks are the same.

The machine type will depend on the final shape to be decorated, however each machine is similar in that they require heating pads made from silicone and a hot plate to melt the decal base. There are a number of manufacturers globally that produce this type of machine.

The speed of application can depend on the production output required by the user. More complex machinery can apply decals at higher speeds, but then more capital investment is needed in the application machinery. As a guide, a person may be decorating 250 mugs manually each day, whereas a semi-automatic machine with manual loading would achieve 2500 in comparison.

Get in touch

International enquiries welcome

- +44 (0) 1782 839464

- +44 (0) 1782 839464

- sales@siaktransfers.com