Specialists in organic low temperature decal

Organic low temperature decal suppliers

Organic low temperature decals can be applied to virtually any substrate. Glass, ceramics, enamels and metals are easily decorated and cured between 150-180 degrees Celsius.

The decals are applied in the same manner as ceramic decals (waterslide). However, in the case of this type of decal, the carrier coating is not burnt away due to the low temperatures being used. The strippable coating as it is known is removed pre or post baking.

The decals are highly flexible and can be applied to complex curved surfaces. The scratch resistance of the final thermally cured decal is similar to that of household varnish. The surface has good solvent resistance, and when correctly cured is compliant with G1 testing.

When used in conjunction with a specific hydrous primer, dishwasher resistance can be achieved, making the decals suitable for decorating stemware glass that would deform under normal ceramic enamel decorating temperatures.

The pigments come in a range of vibrant colours, and include a fluorescent range. The CMYK set is not restricted in the same way as ceramic pigments and the decals rarely need additional colours adding.

Leaders in organic low temperature decals

Uses and applications

- Spirit and wine bottles

- Candle vessels and diffusers

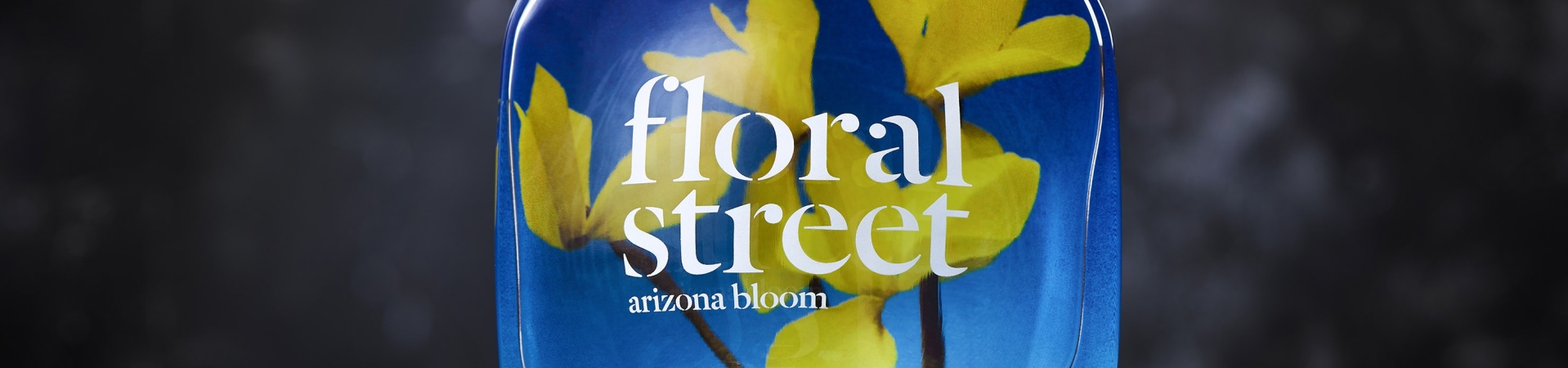

- Perfume flacons

- Olive oil bottles

- Drinking glasses

- Household appliances

- Motorcycle helmets

- Bicycle frames

- Wine and champagne glasses

Common questions

A separate water container has 2-3% of the primer added to it. It is a simple operation of wetting the decorated area with the primer using a brush or sponge. The decal is then placed on top of the treated area and squeegeed down as normal.

Yes, all of our organic decals are free from lead, cadmium and phthalates. Testing documentation is available on request.

Get in touch

International enquiries welcome

- +44 (0) 1782 839464

- +44 (0) 1782 839464

- sales@siaktransfers.com