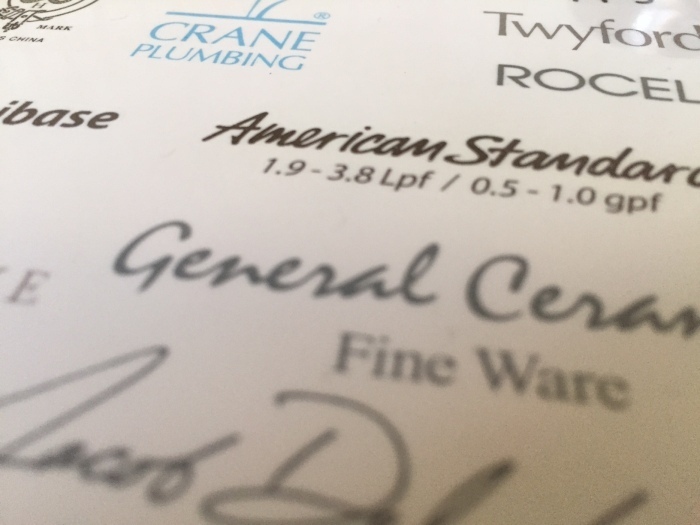

Sanitary decals

Sanitary logos

Decals for sanitaryware must have the highest level of durability due to their exposure to the rigours of industrial cleaning agents and their high use function.

The decals are fired at the highest temperature of all, at around 1200 degrees Celsius.

The logos are applied directly to the powdered green (unfired clay) pieces with the aid of a solvent based decal fixative and fired at glazing temperature. Our expert ceramicists have extensive knowledge of the colour chemistry requirements for this high temperature process.

Sanitary logos decals manufacturers

Uses and applications

- Brand marking toilets and sinks with company logo

- Uniquely marking pieces with country of manufacture

- Adding volume flush rates and similar water usage information

Common questions

A decal fixative (slosh) is a solvent based formula that enables the decal to be placed directly onto the powdered glaze piece. The fixative enables the decal to be placed uniformly and free from bubbles. The fixative is brushed onto the decorated area then the decal is placed in the usual manner and squeegeed down.

Due to the very high firing temperature of this product the colour range is decreased. Colours must remain stable. For example, we suggest that bright blues are particularly challenging as they have the tendency to bleed or run during firing. To add stability to a colour, it is common for us to print a white underneath that after firing is matched to the final white glaze of the piece.

Get in touch

International enquiries welcome

- +44 (0) 1782 839464

- +44 (0) 1782 839464

- sales@siaktransfers.com