Costs, Pricing and MOQ's

- 1. How is the cost of glass and ceramic decals determined?

- 2. How does the quantity of decals affect the cost?

- 3. What are the MOQ's (minimum order quantities)?

- 4. Do the number of colors in the design influence the cost?

- 5. Why do some colors, like pinks and purples, cost more for ceramic decals?

- 6. How do the materials used in the decals impact the price?

- 7. Can I reduce costs by adjusting my design?

- 8. Do bulk orders have any cost advantages?

- 9. How are sample costs calculated?

1. How is the cost of glass and ceramic decals determined?

The cost of decals is influenced by several factors, including the quantity needed, the number of colors in the design, and the materials used. Together, these elements shape the final price of your order.

2. How does the quantity of decals affect the cost?

The quantity of decals impacts the price by determining how many fit on a sheet during production. Larger orders typically offer better value, as the cost per decal decreases with higher quantities due to production efficiencies.

3. What are the MOQ's (minimum order quantities)?

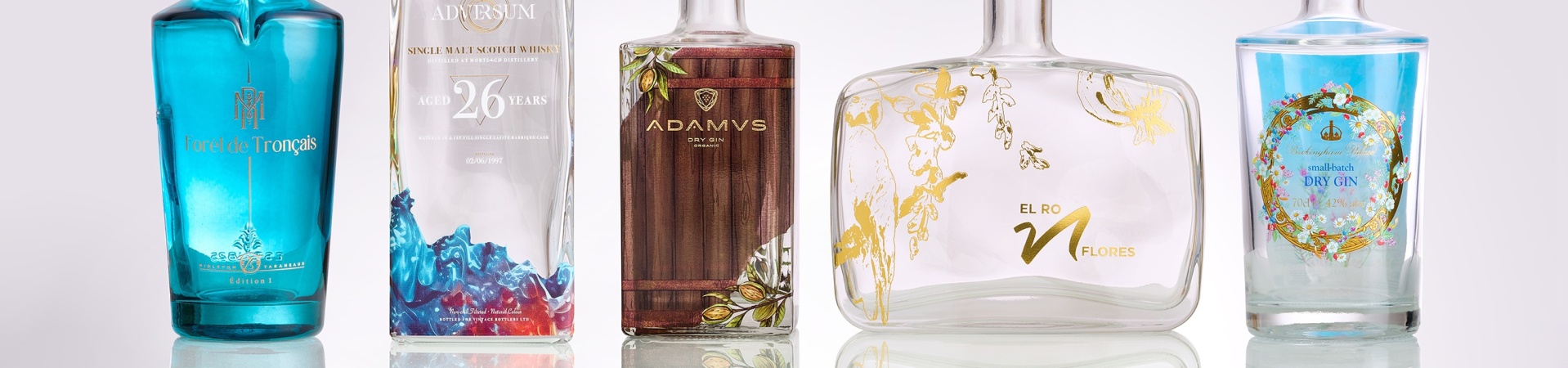

We do not officially have a minimum order quantity. Some of our clients are very high end brands, and thus it is often necessary to produce very small numbers for these extremely expensive products. However, to produce small volumes will mean that the screen and set up costs are not diluted by the number of sheets being printed. This means that the decal can therefore be very high.

4. Do the number of colors in the design influence the cost?

Yes, the number of colors directly affects the price. Each additional color in the design requires more studio time to prepare separate layers for printing, which increases the overall cost.

5. Why do some colors, like pinks and purples, cost more for ceramic decals?

Certain colors for ceramic decals, such as pinks and purples, contain gold as part of their composition. This makes these colors more expensive compared to others.

6. How do the materials used in the decals impact the price?

The cost of components, such as foils, varies depending on their type and color. Specialty foils with unique finishes or rare colors may cost more than standard options. These material costs are factored into the final price of your decals.

7. Can I reduce costs by adjusting my design?

Yes, simplifying the design by reducing the number of colors or choosing standard materials can help lower costs. Our team can work with you to find cost-effective solutions without compromising quality.

8. Do bulk orders have any cost advantages?

Absolutely! Bulk orders benefit from reduced costs per decal due to efficient use of materials and production processes. Ask us for a competitive quote for large quantities.

As all of decals are screen printed, there is a cost to the screens and the amount taken to set up and clean down our machines between each separate colour. If the amount of decals printed is higher, the screen and set up costs are dissipated to a higher degree.

9. How are sample costs calculated?

Sample costs are determined based on two key factors:

The number of colors in your design – Each color adds complexity and increases costs.

Studio time for color separation – Preparing separate layers for each color requires time and expertise.

If you need precise pricing, our team will provide a detailed quote based on your design.

Lead Times and Delivery

- 1. What is the typical lead time for samples?

- 2. How long does production take after sample approval?

- 3. Can delays occur, and how will I be informed?

- 4. Do you ship orders internationally?

- 5. How can I track my delivery?

1. What is the typical lead time for samples?

We usually quote 10-15 working days to produce samples. This timeline allows for careful preparation and quality checks to ensure the samples meet your requirements.

2. How long does production take after sample approval?

Once you’ve approved the samples, production typically takes another 10-15 working days. Note however that lead times may vary if your order is particularly large, or if your design is highly complex. We will communicate any changes to the timeline upfront and keep you informed throughout the process.

3. Can delays occur, and how will I be informed?

While we strive to meet every deadline, delays can occasionally occur due to unforeseen circumstances (each print run we produce can be quite different than the other). If there’s any change to your timeline, we’ll notify you as soon as possible and work with you to minimize any inconvenience.

4. Do you ship orders internationally?

Yes, we ship both domestically and internationally. Delivery times may vary based on the destination, but we work with trusted carriers such as DHL, FED EX and UPS to ensure timely and safe delivery.

5. How can I track my delivery?

Once your order has been shipped, we’ll provide tracking information so you can monitor the progress of your delivery. For international orders, we’ll also assist with any customs-related queries.

Get in touch

International enquiries welcome

- +44 (0) 1782 839464

- +44 (0) 1782 839464

- sales@siaktransfers.com