High quality glass decals

Leading glass decals supplier

SIAK Transfers are the No1 supplier of decals for glass. Our decals can be found decorating the surfaces of the world's most prestigious spirits and cosmetics brands, windows, architectural glass, laboratory items and automotive parts. There are extensive possibilities to suit a range of decoration temperatures. Ceramic enamels for 600 degrees and low temperature organic decals for baking at 150 degrees. A wide variety of effects are available - CMYK high resolution images, Vivid spot colours, Hotfoil stamping and fluorescent colours can be all be achieved. Glass decals are the perfect choice for premium decoration. Relatively low MOQ's make them ideal for limited edition projects and special editions.

Glass decal manufacturers

Uses and applications

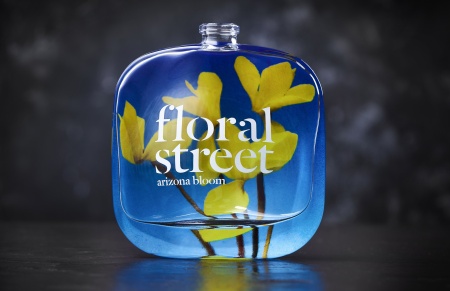

- Spirits & Liquor: Achieve premium, multi-colour branding—even on complex or uniquely shaped bottles—perfect for limited editions and high-value releases where direct print isn’t an option.

- Cosmetics: Elevate packaging with rich, multicolour designs and hotfoil accents for a high-end look. Our decals are thermally cured to meet the highest durability standards.

- Candles & Diffusers: Enjoy full 360° decoration—including mirror image effects—so your design shines from every angle, inside and out.

- Drinkware: Enhance glasses and stemware with vivid, dishwasher-resistant decals for long-lasting brand impact.

- Laboratory & Safety: Rely on precision decals for identifying lab glassware and displaying safety standards on glazing and architectural glass.

Common questions

SIAK manufactures two types of glass decals - Ceramic and Organic.

Ceramic glass decals typically require firing temperatures that fall within the range of 1020°F to 1450°F (550°C to 790°C), but the optimal temperature depends on the specific type of decal and glass being used. A much lower temperature of around 1020°F to 1250°F (550°C to 675°C) is sometimes used, which allows the design to adhere to the glass surface without altering its form. Higher temperatures, closer to 1450°F (790°C), may be required for certain applications, particularly when fusing glass layers.

Occasionally referred to as cold decals, organic decals are baked to the surface at just 150 - 180 degrees celsius. This relatively low temperature gives energy saving benefits to the end user.

Glass ceramic decals, while versatile and vibrant, do have certain color limitations due to the materials and firing processes involved. The range of colors that can be achieved is often restricted by the pigments and oxides that are stable at high temperatures.

Organic decals, on the other hand do not have such restrictions. Vivid colours including bright pinks and even fluorescent pigments can be attained.

Get in touch

International enquiries welcome

- +44 (0) 1782 839464

- +44 (0) 1782 839464

- sales@siaktransfers.com