Cosmetics sector decals

Decals for cosmetics products

For cosmetic companies seeking impeccable quality in decal production, SIAK stands as the go-to solution. SIAK leverages cutting-edge printing technology that surpasses industry standards.

Our facility is equipped with innovative machinery capable of achieving intricate, high-resolution details, vivid colours, and flawless finishes. Whether it’s metallic foiling, textured effects, or ultra-fine gradients, SIAK's technology guarantees every detail is executed to perfection.

Whether you’re launching a small-batch luxury product or preparing for a global cosmetic line, SIAK delivers tailored solutions at any scale. Our ability to manage large-scale production without compromising quality makes us the ideal partner for dynamic and growing brands.

Partnering with SIAK doesn’t just mean obtaining beautiful decals; it means elevating your brand. Our innovative technologies, passion for design, and dedication to quality ensure every product leaves a lasting impression.

Decal supplier for cosmetics industry

Uses and applications

Transform your cosmetics packaging with SIAK – where expertise meets innovation, and every detail is a statement.

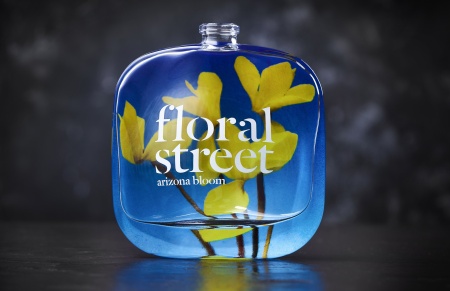

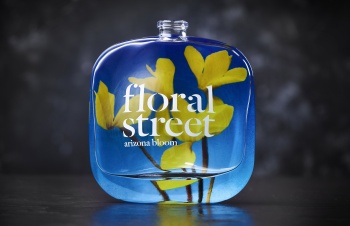

- Perfume Bottles - A perfume bottle is as much an ornament as it is a functional product. SIAK’s decals can incorporate metallic sheens, gold accents, or textured details, turning perfume bottles into elegant keepsakes that reflect the scent’s sophistication.

- Perfume flacons - Flacons often represent exclusivity and tradition in perfumery. SIAK’s expertise allows for harmonious integration of intricate designs that maintain the flacon's timeless aesthetic while adding a modern edge with touchable textures or delicate embellishments.

- Face Cream Jars - While functionality is key for skincare, beauty counts here too. A face cream jar printed with delicate floral decals for example, and combined with minimalistic branding, feels serene yet glamorous. This aesthetic choice evokes both confidence in product quality and indulgence.

- Premium Hand Washes - Hand washes are more than just functional—they're becoming a home décor statement. Custom brand decals elevate these everyday items into gifting-worthy treasures.

- Perfume Vials - These small vessels often house rare, concentrated scents and demand packaging that matches their exclusivity. The small size of the product makes detailed, high-quality decals an ideal choice.

Supplier of cosmetics decals

Decals for cosmetics

Glass enamel decals

Ceramic decals for glass are fused to the glass at high temperature. Their key advantage is their ability to withstand wear and tear from frequent use or environmental factors.

Heat release decals

With decorating speeds upwards of ten times faster than that of hand application, and with consistent placement. The automated decal system is ideal for factories looking to increase their output.

Hot foil decals

Hot foil decals in a multitude of effects can be placed into areas not normally accessible to foil stamping. Bottle necks, and full wraps with large foil areas are all possibilities.

Organic low temperature decals

Organic decals offer a low temperature, and thus energy saving alternative way to decorate glass and certain ceramic surfaces. Vibrancy of colour is not restricted in the same way as that of inorganic compounds.

Get in touch

International enquiries welcome

- +44 (0) 1782 839464

- +44 (0) 1782 839464

- sales@siaktransfers.com