Decal suppliers for the tableware sector

Decals for the tableware sector

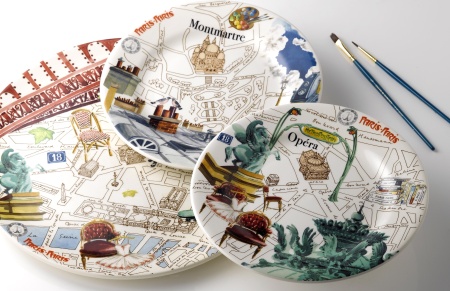

At SIAK, we are dedicated to delivering unparalleled excellence in the manufacture of ceramic tableware decals and transfers. Trusted by tableware manufacturers for our precision, craftsmanship, and innovation, we consistently set the benchmark for quality in the industry.

Precision is our promise. With five state-of-the-art Sakurai Maestro machines, we ensure each decal is produced with flawless accuracy and consistency. These advanced printing systems are engineered for excellence, allowing us to create intricate designs with vibrant colours that transform ceramic tableware into works of art.

When it comes to enhancing the appearance and durability of ceramic tableware, SIAK provides a wide range of expertly crafted decals designed to suit diverse needs. From waterslide to automated decals, and the relevant firings types of onglaze, inglaze, and underglaze, we deliver precision and quality for every ceramic substrate.

Decals and transfers for ceramic tableware

Uses and applications

When you work with SIAK, you’re not just getting incredible decals—you’re gaining a partner committed to helping your ceramics stand out. Whether you need custom designs or large-scale production, we’re here to deliver precision, quality, and distinction that sets your brand apart.

- Enhance visual appeal on porcelain, stoneware, bone china and earthenware tableware with intricate decal designs.

- Use onglaze decals for vibrant, glossy finishes ideal for decorative pieces.

- Apply inglaze decals for a seamless, durable finish resistant to wear and scratches.

- Integrate underglaze decals for unparalleled durability and deep integration with ceramic surfaces.

- Employ manual application, or leverage heat transfer technology for efficient, high-volume decal applications on tableware.

- Create custom branding and patterns to differentiate products in competitive markets.

- Adapt to various tableware forms such as plates, cups, bowls, and servingware with flexible decal techniques.

Supplier of tableware decals

Decals for tableware

Ceramic relief decals

Relief or emboss decals add texture and shape to the surface of a ceramic glaze. The technique known as white on white adds a subtle yet sophisticated finish to the decorated article.

Heat release decals

With decorating speeds upwards of ten times faster than that of hand application, and with consistent placement. The automated decal system is ideal for factories looking to increase their output.

Inglaze decals

Enhanced mechanical and dishwasher durability for high use items. The inglaze technique also provides a smooth and seamless finish.

Metallic effect decals

Mica metallic decals for ceramics present a striking option for adding a touch of sparkle and sophistication to ceramic designs without the associated cost of using actual precious metal pastes.

Onglaze decals

Onglaze decals are fired at high temperature and fuse to the surface of the glaze. Colours can be combined with metallic and relief effects which are fired at similar temperatures.

Underglaze decals

Applied to bisque ware, and then fired to harden the image to the piece followed by the glazing process that completely seals the image providing very high levels of durability.

Get in touch

International enquiries welcome

- +44 (0) 1782 839464

- +44 (0) 1782 839464

- sales@siaktransfers.com